Tin Tức

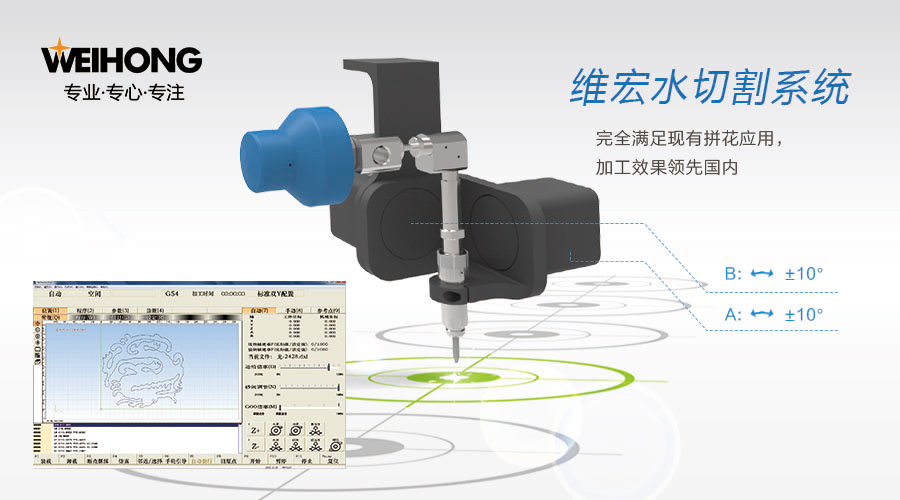

[Product Promotion] Shanghai Weihong AB Five-axis Water Cutting System

The “embarrassment” of the effect of AB five-axis machining

Shanghai Weihong’s original absolute advantage

focuses on improving the unsatisfactory results of domestic five-axis water cutting processing. Shanghai Weihong selects key personnel for research and development to investigate the current status of five-axis waterjet companies at home and abroad, and collects relevant technical data from multiple parties to process paths Optimized and repeatedly passed the trial cutting verification, an upgraded version of the AB five-axis water cutting system was launched.

Shanghai Weihong AB 5-axis water cutting system provides excellent processing results, especially in the processing of sharp corners and complex graphics.

We present a high-quality sharp corner effect. When the

AB axis travel is sufficient, continuous non-stop cutting at the corners is achieved.

When the stroke of the AB axis is not enough, the vector change and the speed of the axis are optimized to ensure smoothness at sharp corners.

We guarantee excellent system performance and

provide the best cutting method for circular arc joints with different curvatures, effectively avoiding tool marks on the workpiece surface due to the pause of the cutting point.

Optimize the feed speed for cutting complex graphics to avoid continuous fluctuations in speed caused by machine shake and ensure the smooth surface of the workpiece.

We provide user-friendly auxiliary products.

Considering the complex processing steps of the water cutting processing site, Shanghai Weihong has introduced the water cutting wireless handle in a “customer-oriented” design concept, which can greatly facilitate the user to operate the machine tool and improve manual operation. Operational efficiency saves a lot of time.