|

|

DriveWISE series servo drives are widely applied in fields of woodwork, 3C, metal engraving and milling, cold cutting, laser cutting, robots,…

|

In response to the demand for motion control system with high performance and the thirst for precise positioning,Weihong company, by unswervingly striving for excellence and innovation, launches WISE series servo drive which covers servo motor from 0.1kW to 3.0kW, enabling precise control on position, speed, and torque.

|

|

DriverIn order to meet the high performance demand of motion control system raised by industrial control market, and the thirst for precise positioning raised by machine tool builders, Weihong company, by unswervingly striving for excellence and innovation, launches WISE series servo driver, which proves to be another successful application in motion control industry chain. |

|

Applicable Models:

Woodworking industry

Carved / Panel Furniture / Stone Jade Carving / Advertising

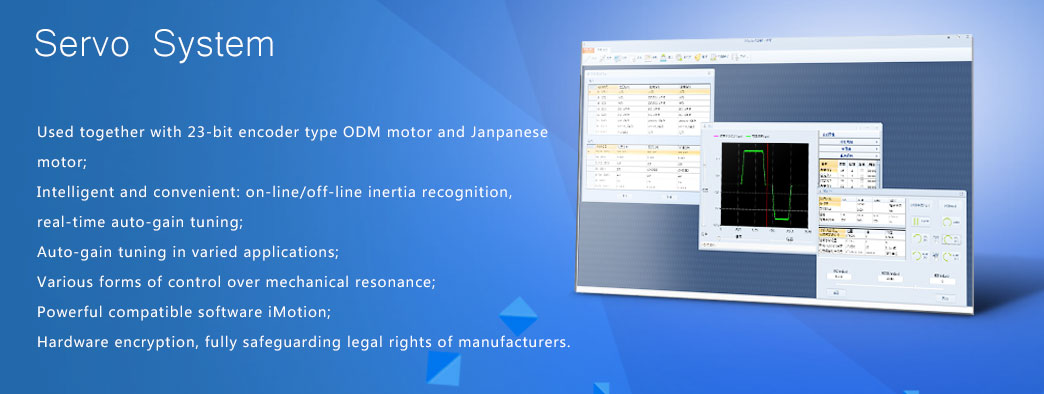

Servo System

Driver/Motor

1. It is used in the relief and panel furniture industries, with simple debugging, automatic acquisition of inertia ratio, and automatic gain adjustment;

2. Absolute encoder motor is used, eliminating the tedious steps of returning to the mechanical origin before starting up and reducing the failure caused by the origin switch;

3. Aiming at the problem that the motor is prone to resonance caused by the large machine tool travel in this industry, Weizhi adopts a unique algorithm to obtain the resonance point in real time and filter out the resonance.

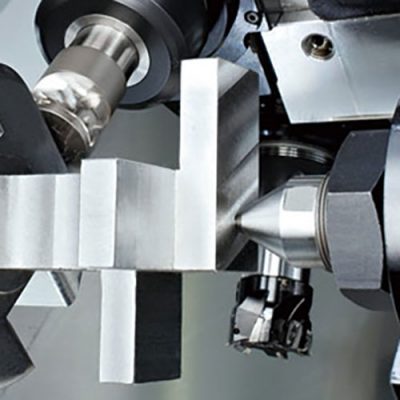

Metal industry Metal mold / glass engraving / denture industry Servo System Driver/Motor

1. Excellent low-speed smoothness, ensuring clearer engraving details and brighter surface; the use of absolute encoder motor eliminates the tedious steps of returning to the mechanical origin before starting and reducing the failure caused by the origin switch

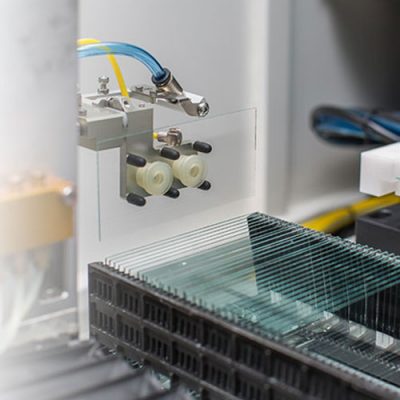

3C industry

Glass edging / metal highlight

Servo System

Driver/Motor

1.According to the characteristics of the industry, select ODM motors of well-known manufacturers to ensure the low-speed stability of the motors, making the workpiece corner grinding more smooth;

2. Servo and motor reach IP65 protection level, effectively reducing the impact of high temperature and high humidity processing environment on servo and motor;

3. Absolute encoder motor is used, eliminating the tedious steps of returning to the mechanical origin before starting the machine and reducing the failure caused by the origin switch.

Robot industry Servo System Driver/Motor

Manipulator

Excellent servo control algorithm, greatly shorten the machine setting time and reduce the preparation time for debugging.

|

|

AdvantageUsed together with 23-bit encoder type ODM motor and Janpanese motor; Intelligent and convenient: on-line/off-line inertia recognition, real-time auto-gain tuning; Auto-gain tuning in varied applications; Various forms of control over mechanical resonance; Powerful compatible software iMotion; Hardware encryption, fully safe guarding legal rights of manufacturers.

|