|

|

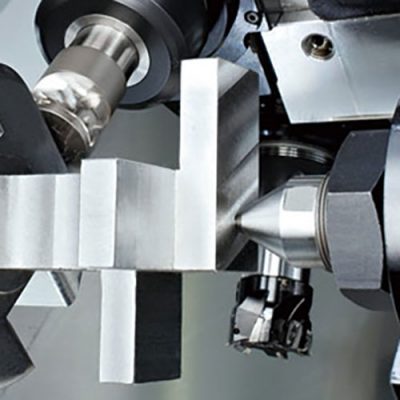

Waterjet CuttingIt has been widely applied in cutting metal, stone, glass, ceramic,… |

The system covers motion control solutions over 2~5 axes, among which five-axis waterjet cutting CNC system, is the earliest and most mature system in domestic market. It can achieve dynamic five-axis cutting and solve the tapper and trailing problems of high-pressure waterjet technology.

|

|

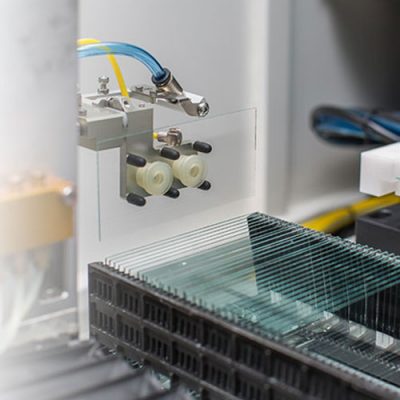

Glass CuttingIt has been widely applied in machining glasses for different uses, e.g. architecture, home appliance, photoelectricity, PV, mobile phone, glass splicing,…

|

The system boasts leading functions such as following normal line of the rotary-axis, eccentricity compensation, precise cutting pressure control by analog quantity.

Water cuttingWeihong water cutting control system covers a full range of motion control solutions from two-axis to five-axis. The five-axis water cutting system can achieve dynamic five-axis cutting and solve process problems such as taper and tailing of high-pressure water jets. It is a domestic Application of earlier and more mature water cutting control systems. It is mainly used in cutting metal, stone, glass, ceramic and other industries.

Glass cuttingWeihong glass cutting control system has advanced functions such as rotation axis normal follow, cutter wheel eccentricity compensation, and precise control of cutting pressure by analog quantity. It is widely used in architectural glass, home appliance glass, automotive glass, photoelectric glass, photovoltaic glass, mobile phone glass, Glass cutting industry such as mirrors. |

|

Applicable Models:

Weihong Control System Integrated 2.17GHz dual-core CPU, 60G solid-state hard disk, 2G memory, control card unit, NcStudio motion control software, etc., excellent hardware performance; "Communication card + Ronda controller", using serial communication, 485 interface, baud rate 10Mbps, good real-time performance;

Five-axis AB water cutting machine

Suitable for stone pattern, ceramic pattern

5-axis AC water cutting machine Weihong Control System PM95A

Suitable for 3D large-angle cutting, slate cutting

Integrated 2.17GHz dual-core CPU, 60G solid-state hard disk, 2G memory, control card unit, NcStudio motion control software, etc., excellent hardware performance;

"Communication card + Ronda controller", using serial communication, 485 interface, baud rate 10Mbps, good real-time performance;

Two-dimensional graphics with bevel cutting are more efficient and effective. Can achieve 45 degrees and other large angle cutting. Can achieve high-precision 3D cutting. It can support the import of two-dimensional graphics to realize circular three-dimensional cutting.

Weihong Control System Integrated 2.17GHz dual-core CPU, 60G solid-state hard disk, 2G memory, control card unit, NcStudio motion control software, etc., excellent hardware performance; "Communication card + Ronda controller", using serial communication, 485 interface, baud rate 10Mbps, good real-time performance;

Multifunctional automatic cutting machine

Suitable for special-shaped glass cutting and mirror matching

|

|

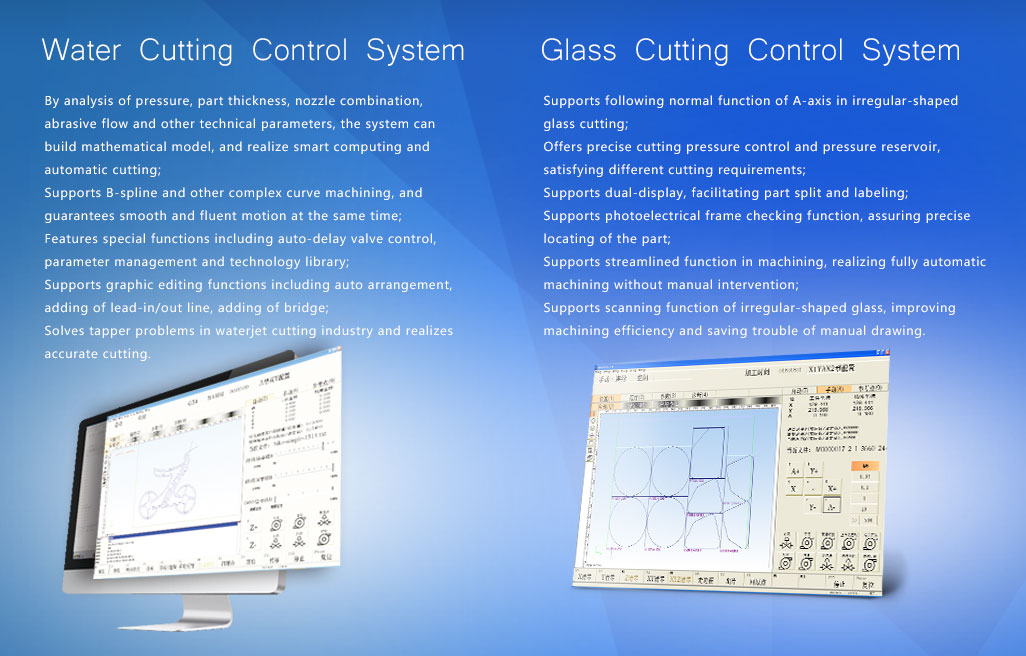

Waterjet Cutting Control SystemBy analysis of pressure, part thickness, nozzle combination, abrasive flow and other technical parameters, the system can build mathematical model, and smart calculation and automatic cutting; Support B spline and other complex curve machining, and guarantee smooth and fluent motion at the same time; Feature special functions including auto-delay valve control, parameter management and technology library; Support graphic editing functions including auto arrangement, lead-in/out line, bridge edition; Solve tapper problems in waterjet cutting industry and realize accurate cutting.

|

|

|

Glass Cutting Control SystemOffer precise cutting pressure control and pressure reservoir, satisfying different cutting requirements. Support streamlined function in machining, realizing fully automatic machining without manual intervention. Support photoelectrical frame checking function, assuring precise locating of the workpiece. Support scanning function of irregular-shaped glass, improving machining efficiency and saving trouble of manual drawing. Support dual-display, facilitating workpiece split and labeling.

|

Ứng dụng

Adopt AC five-axis high-precision system to achieve 3D three-dimensional cutting; use four or five-axis system to achieve bevel cutting, widely used in stone, ceramic parquet industry; metal sheet metal processing; flexible control of high and low voltage conversion process to cut special-shaped glass.

Provide fast straight glass cutting; for complex graphics, provide normal follow function to support profile cutting; provide precision profile cutting for home decoration, apply to mirror industry.