Integrated CNC Controller NK300 Series

NK300CX-H / NK300BX-H / NK300BX-V

NK300CX Integrated CNC System

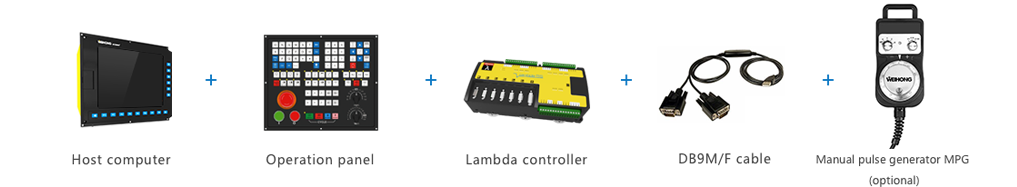

NK300CX uses industrial grade motherboard for high-end engraving and milling machine, CNC machine and machining center and so on. According to different electronic cabinet sizes, NK300CX is designed two models: horizontal and vertical. Each model can be combined with different software to realize different functions such as three-axis/four-axis linkage and double-Y drive.

|

|

• Dual-core CPU processor, faster response and stronger functions.

• Simpler HMI, more user-friendly and easier to operate.

• Support 4 axes linkage with Mechatrolink.

• Support many synthesized compensation functions, like lead screw error compensation, and directly importing compensation file.

|

Parameter Configuration:

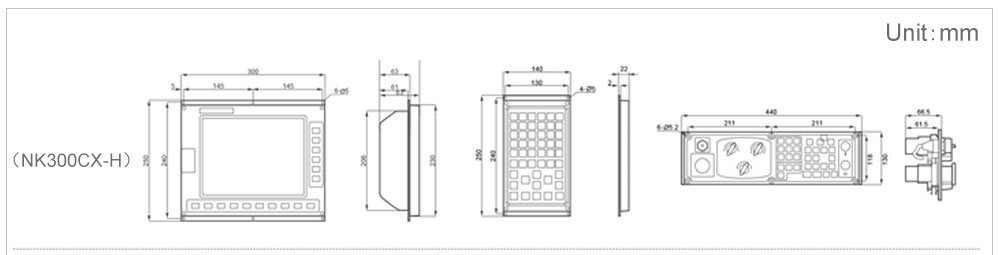

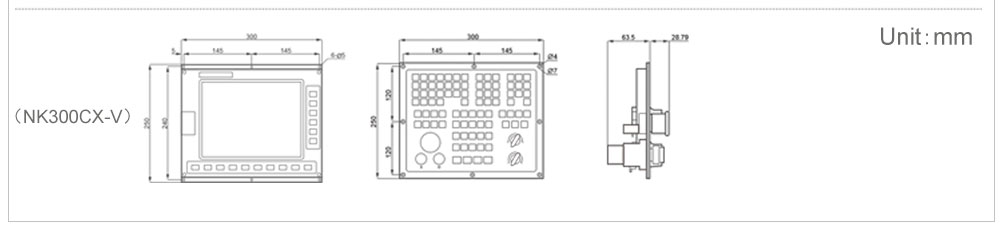

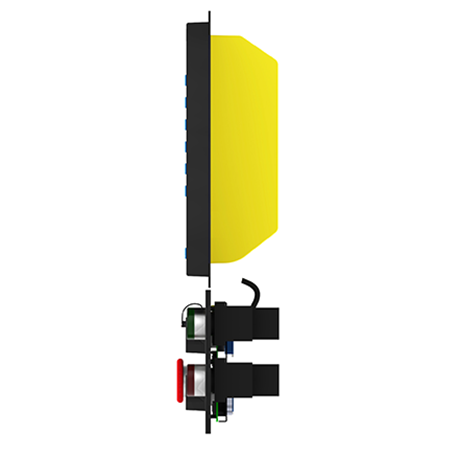

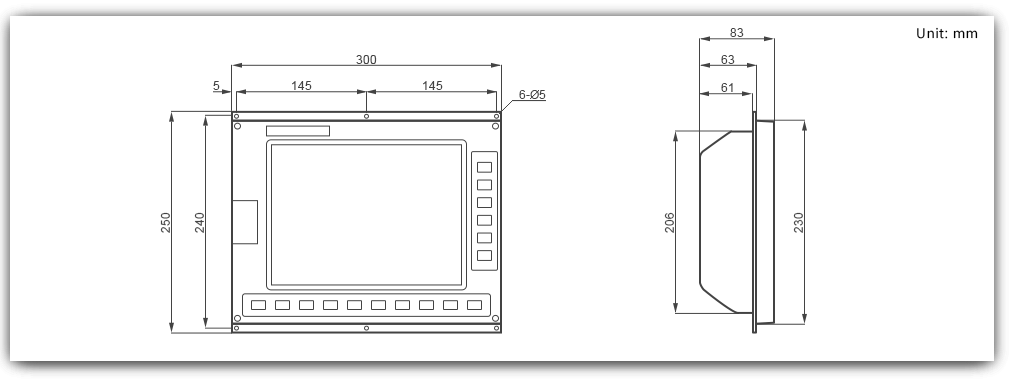

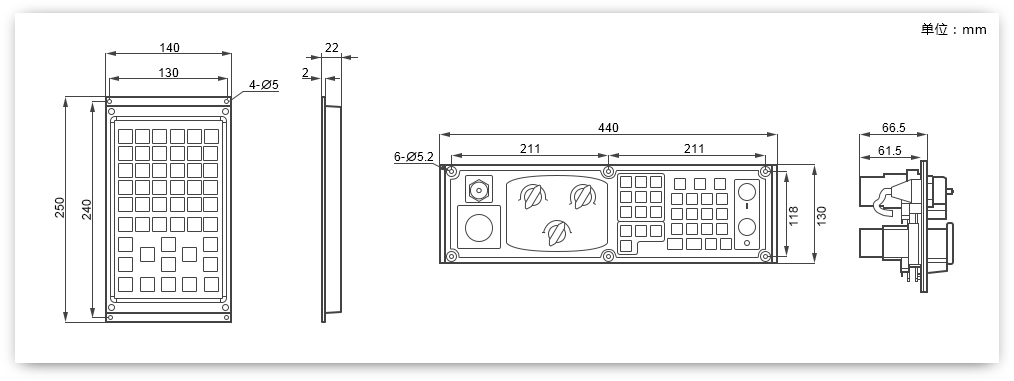

Mounting Dimension

- Host computer dimension figure and bore hole drawing

- Keyboard dimension figure and bore hole drawing

| Thông số kỹ thuật | ||

|---|---|---|

| CNC specifications | Number of Axes Supported | 3-5 axes |

| Hardware specifications | CPU | Dual cores |

| CPU Clock Speed | 2.17GHz | |

| RAM | 2GB | |

| Storage | 60GB | |

| Monitor Dimension | 10.4 inches | |

| Monitor Resolution | 800×600(SVGA) | |

| I / O number | Standard: 28/8; Extended terminal board: 8/8(non-cascade connection),10/10 (cascade connection) | |

| Performance Indicator | The product stands EMI/Electrical fast transient immunity/Surge immunity tests and conforms to the fourth grade protection standards of GB/T 17626.5-2008. Resistance to vibration conforms to the GB/T 2423.10-2008 Standards. The product stands rigid temperature tests and conforms to the industrial standards of GB/T 2423.102-2008. |

|

| Spindle | Analog Voltage Output | 0 - 10V |

| Tool management functions | Tool Magazine Type | Linear tool magazine, Disk-type tool magazine |

| Tool setting mode | Auto measurement, Manual measurement | |

| Tool setting type | Fixed calibration, Mobile calibration, First calibration & Calibration after tool change | |

| Compensation function | Compensation type | Screw error compensation, backlash compensation, over-image error compensation, tool compensation |

| Circular Interpolation | Three axes linkage | |

| Communication | Internet (Ethernet) | LAN communication, Front USB interface, Two-way transmission between the system and PC |

| Toolpath Program | Supported File Format | * .g; * .nc; * .ug; * .demo; * .iso; * .eng; * .cut; * .dxf; * .plt; * .txt |

| Operations | Coordinate system setting / WCS Setting | Supporting WCS G54-G59 and 120 extended WCSs |

| Processing technology | Array function, Mirror&rotate, Multi-layer machining, Cycle machining | |

| High-speed High-precision Optimization | Multiple interpolation algorithms | S-type, LEP and Acceleration T-type algorithms |

| Language | Chinese, English | |

| Reliability & Safety | NC software alarm | Alarms of program error, operation error, over-travel error, PLC error and IO communication error |