Integrated CNC Controller NK200 Series

NK260 / 280 / 280B

IPC series: NK260/280/280B

NK200 series is widely applied in the fields of CNC engraving and milling machine/engraving machine. It owns high reliability and high cost performance, supports 4-axis linkage, Yaskawa M-II and WISE bus communication and absolute encoder, and serial communication. And its I/O ports can be extendable. Matched with 8-inch LCD screen and embedded platform, secondary development of technics is available.

|

|

• Strong secondary development.

• Serial communication and extendable I/O ports.

• High real-time embedded system with better performance and more stability.

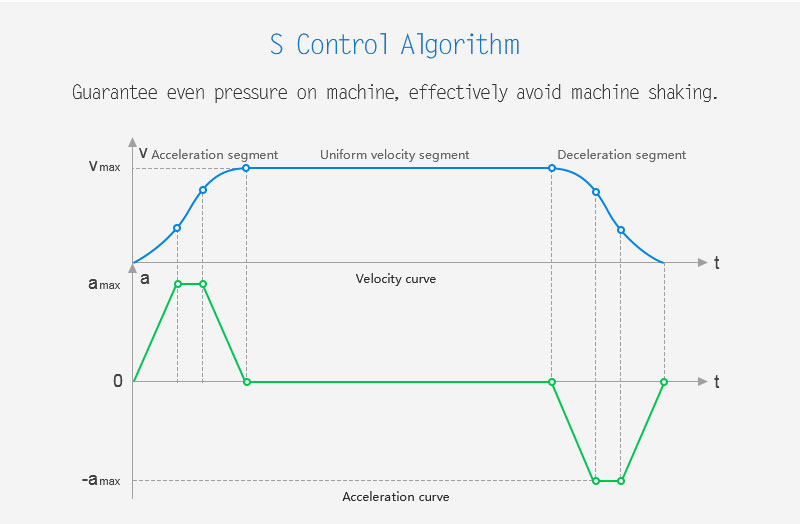

• Adopt S-type control algorithm to ensure uniform force on the machine tool and effectively prevent machine shake.

|

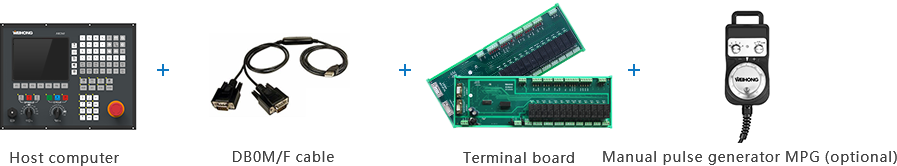

Product Configuration:

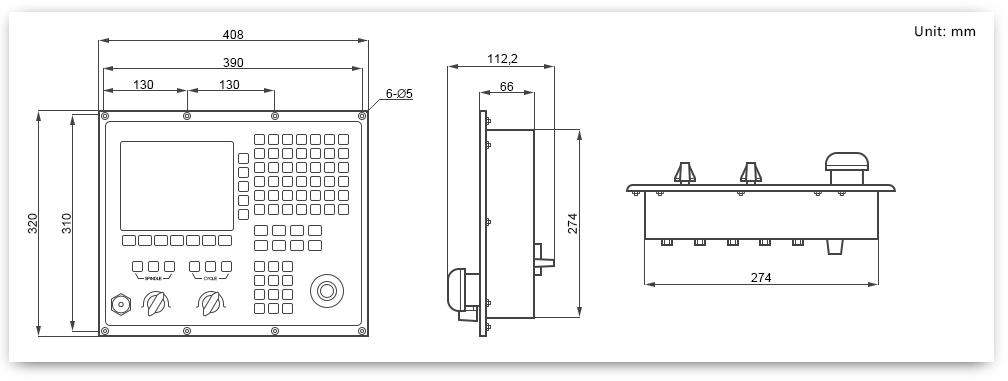

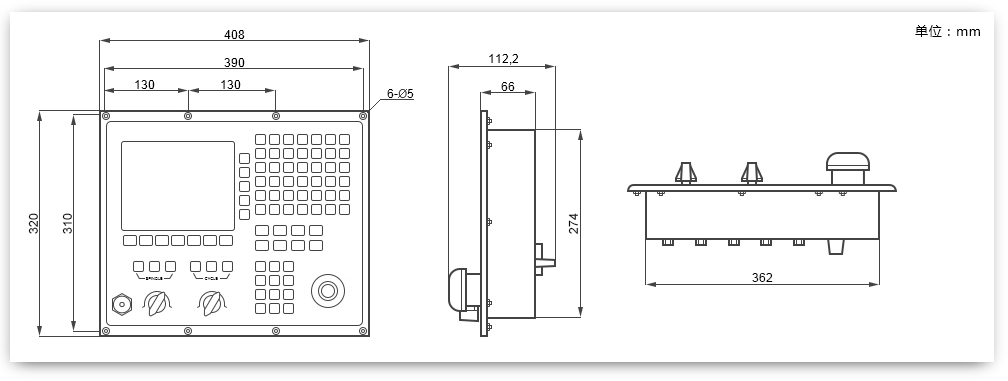

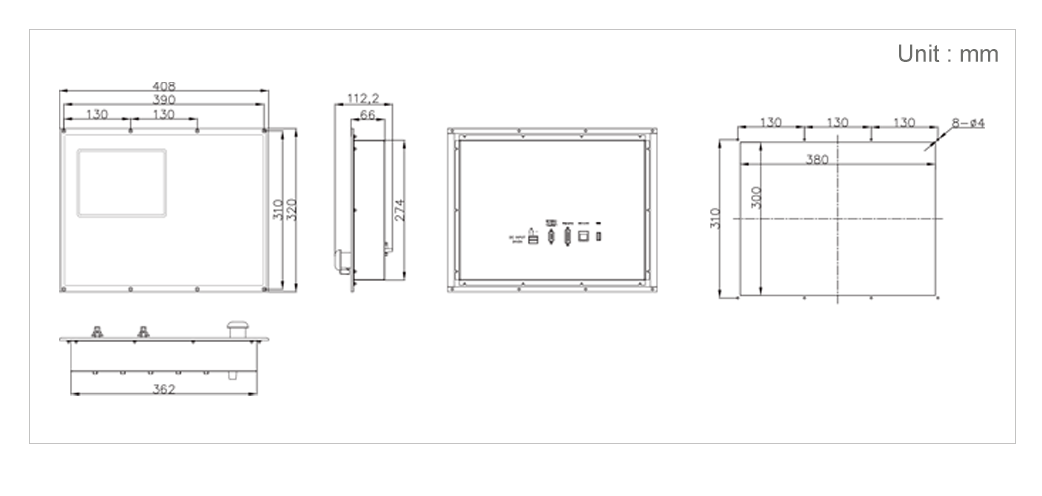

Kích thước lắp đặt:

| Thông số kỹ thuật | ||

|---|---|---|

| CNC specifications | Standard control axes | 3 Axes |

| Hardware specifications | CPU | ARM11 / Arm Cortex-A8 |

| Clocked at | 600MHz / 800MHz | |

| Memory | 128MB / 512MB | |

| Flash | 256MB / 512MB | |

| Monitor Dimension | 8 inches LED | |

| Monitor Resolution | 800 × 600 | |

| I / O number | Standard: 16/16; Extended terminal board: 10/8 (cascade connection), maximum support for expansion: 4/4 (non-cascaded) total of 80 inputs and 80 outputs | |

| Performance Indicator | The product stands EMI/Electrical fast transient immunity/Surge immunity tests and conforms to the fourth grade protection standards of GB/T 17626.5-2008. Resistance to vibration conforms to the GB/T 2423.10-2008 Standards. The product stands rigid temperature tests and conforms to the industrial standards of GB/T 2423.102-2008. |

|

| Spindle | Analog Voltage Output | 0 - 10V |

| Tool management functions | Tool Magazine Type | supports in-line and disc tool magazines |

| Tool setting mode | supports automatic and manual tool setting | |

| Tool setting type | fixed tool setting, floating tool setting, first tool setting / tool setting | |

| Compensation function | Compensation type | Screw error compensation, backlash compensation, over-image error compensation, tool compensation |

| Communication | Internet (Ethernet) | set up LAN, front USB interface, realize bidirectional transmission with PC |

| Toolpath Program | Supported File Format | * .g; * .nc; * .ug; * .demo; * .iso; * .eng; * .cut; * .dxf; * .plt; * .txt |

| Operations | Coordinate system setting / WCS Setting | Supports G54-G59 coordinate system, support extended coordinate system |

| Processing technology | Array function, rotation mirroring, layered processing, cycle processing | |

| Convenient operating | Hand wheel guide, ahead of the point, tool selection processing | |

| High-speed High-precision Optimization | Multiple interpolation algorithms | T-shape and S-shape |

| Language | Chinese, English | |

| Reliability & Safety | NC software alarm | Alarms of program error, operation error, over-travel error, PLC error and IO communication error |