Integrated CNC Controller NK210T Series

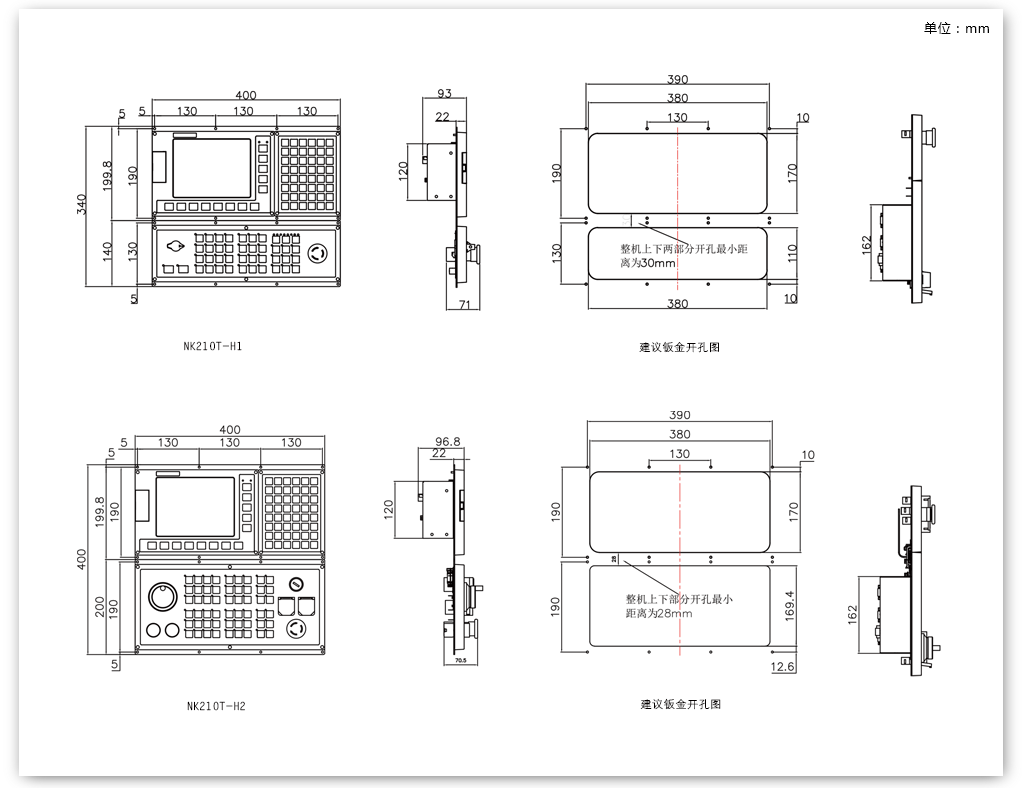

NK210T-H1

NK210T-H2

Product configuration:

Kích thước lắp đặt:

| Thông số kỹ thuật | ||

|---|---|---|

| CNC specifications | Standard control axes | triaxial |

| Hardware specifications | CPU | ARM11 |

| Clocked at | 600M | |

| Memory | 128M | |

| Flash | 256M | |

| Display size | 8-inch LCD screen | |

| Display resolution | 800 × 600 | |

| I / O number | standard: I38 / O18, I27 / O8, expandable | |

| The performance index has | been tested by electromagnetic interference, group pulse and surge. The product has reached the fourth level of protection standard GB / T 17626.5-2008. The shock resistance is in accordance with the standard GB / T 2423.10-2008. -2008) |

|

| G code system | Type | A / B / C |

| Tool management functions | Including positioning, linear interpolation, circular interpolation, thread cutting and interpolation, plane selection, reference point workpiece coordinate system, local coordinate system, tool measurement, tool compensation, single fixed cycle command, compound fixed cycle command, pause, etc. | |

| Interpolation function | G00, G01, G02, G02.1, G02.2, G03, G03.1, G03.2, G32, G34 | |

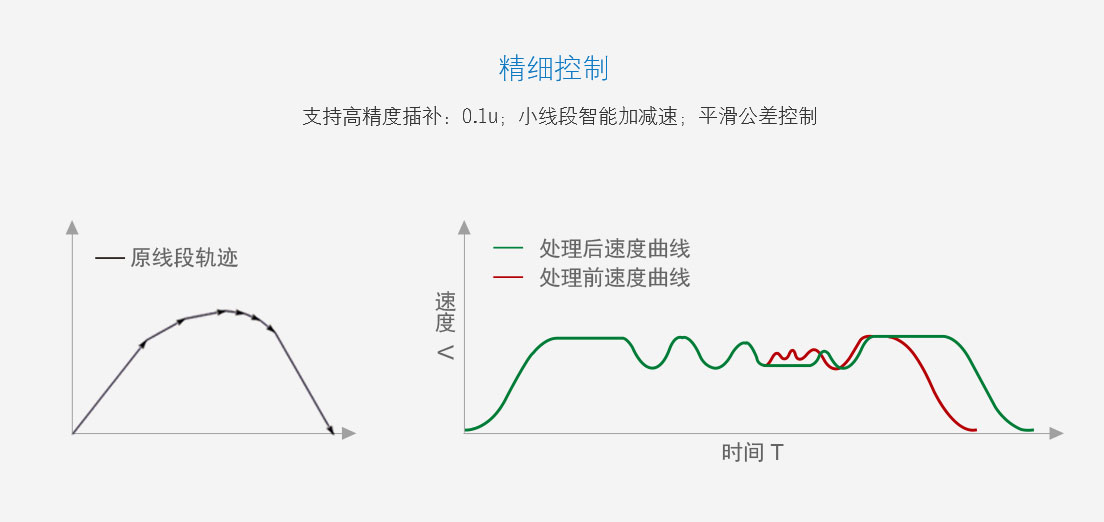

| Feed function | Maximum fast speed: 120000mm / min, maximum feed speed: 48000mm / min before acceleration and deceleration control, speed smooth control, corner control, track smoothing function, pre-reading feed rate: 0 ~ 120% (16 gears) open PLC Ladder diagram editing |

|

| Thread function | Single head / multi-head thread, metric / inch thread, straight thread / taper thread / face thread, constant pitch / variable pitch thread withdrawal length, angle and speed can be set. Digital spindle thread pitch: 0.01 ~ 500mm (metric), 0.06 ~ 25400 teeth / inch (imperial) |

|

| Spindle function | Bus spindle, analog spindle, digital spindle analog spindle automatic / manual gear shifting, digital spindle positioning, support digital spindle "speed / position" mode switching spindle override: 50 ~ 120% (level 11), analog voltage: 0 ~ 10V (stepless ) 1 spindle encoder feedback, the number of encoder lines can be set when the spindle is running, chuck control, spindle constant linear speed control (G96 / G97) |

|

| Tool function | 3-axis tool compensation (X / Z / Y), number of tool offsets: 32 sets of tool length compensation, tool radius compensation: ± 999.999mm / ± 99.9999inch 3-axis tool compensation (X / Z / Y), tool offset number : 32 sets of tool length compensation, tool radius compensation: ± 999.999mm / ± 99.9999inch |

|

| Program storage and editing | Program capacity: 512M (built-in), unlimited number of program storage, support DNC online processing program programming: relative programming, absolute programming, mixed programming, decimal point program editing: program typing, modification, deletion, insertion, retrieval, replacement, check wrong and other multi-MDI program editor, run a subroutine call |

|

| Program check function | Fast graphic drawing of program track, dry running, single-stage running, etc. | |

| Compensation function | Tool length compensation, tool nose radius compensation (G40, G41, G42) Backlash compensation: 0 ~ 8mm, pitch error compensation per point compensation: ± 0.1mm |

|