Tin Tức

“Stone” Responsibility 丨 Weihong stone processing overall solution upgrade

Look at the stone, see the trend, rely on the “stone” force!

Weihong’s overall stone processing solution leverages decades of experience in the CNC industry and provides users with a more intelligent and efficient stone processing experience through excellent motion control algorithms .

slate and other stone products for deep processing of

plate material, kitchen countertops, stone carving crafts, shaped lines …

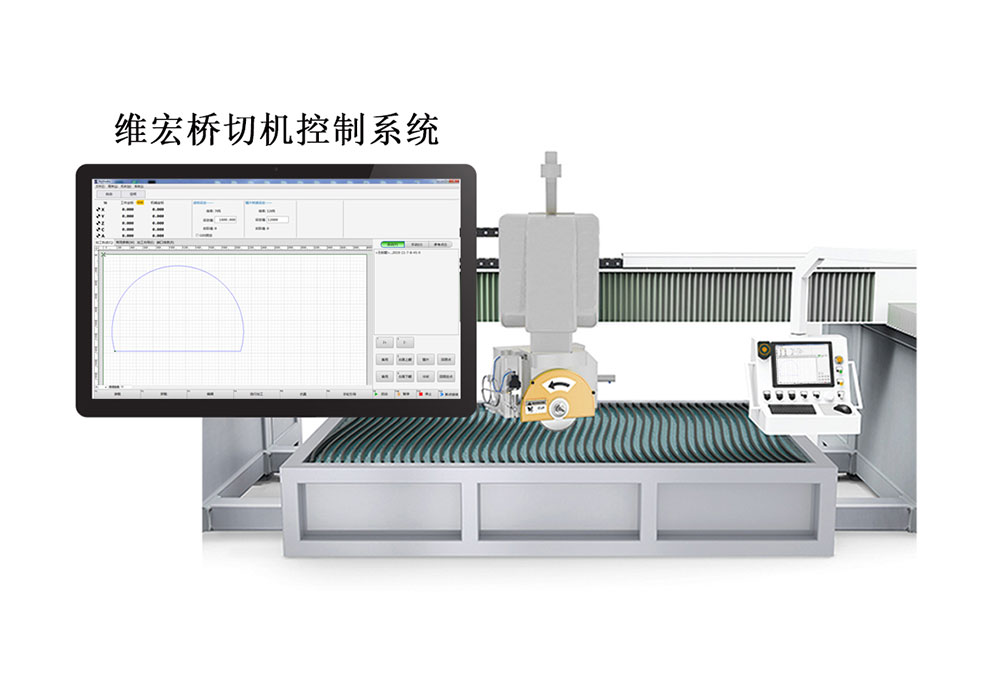

Stone bridge cutting

Aiming at the problems of traditional bridge cutting with difficult layout, low processing efficiency, and low plate utilization, Weihong introduced a more automated bridge cutting machine control system.

Processing Wizard Function

For basic processing requirements, you do not need to use a third-party software for tedious drawing or programming. You can use the processing wizard to generate a tool path file for direct processing.

- A variety of practical linear cutting modules: single cutting, multiple cutting, orthogonal cutting, specification boards;

- Support multiple format toolpath files to directly import cutting modules: .DXF, .DWG, .G, .NC, .PLT, .ENG;

- Library module: Select the graphic template in the library, set the graphic parameters, and generate the machining toolpath.

C axis normal follow

Control the cutting direction of the saw blade always perpendicular to the normal of the processing graphics to ensure the quality and efficiency of the cutting workpiece.

Automatic tool setting function

Continuous upgrade

☑ Large board photo: intelligent alignment

吸 Suction plate transfer: assembly line operation

☑ Thickness detection: automatic detection of material thickness

☑ Intelligent typesetting: maximization of plate utilization

☑ Automatic labeling: Simplified process, more convenient for packaging and paving

…

Stone processing center 3.0-

dimensional macro stone processing center control system is mainly used for grinding and processing of special-shaped stone kitchen and bathroom special-shaped lines such as countertops and washbasins. Version 3.0 adds advanced functions such as special-shaped processing and linear compensation of grinding wheels, which solves the problems of low processing efficiency and difficult recruitment of stone kitchens.

Processing technology

Grinding wheel compensation

Stone carving

File second-level loading

Supports the second-level loading of Jing ENG (including version 5.53) files.

Near the point to continue

near the point to continue processing enables customers Duandao continued cutting more convenient.

Waterjet five-axis solution

Weihong’s five-axis water cutting system can realize dynamic five-axis cutting and solve the technical problems of taper and tail of high-pressure water jet. It is an earlier and more mature water cutting control system in China. It is mainly used for cutting metal, stone, glass , Ceramics and other industries. It currently occupies the main domestic market share and is gradually moving towards the international market.

AC axis error compensation

Slot Compensation

Automatically compensates the trajectory according to the actual slot size to ensure accurate workpiece size and greatly reduces the workload of the draftsman.

lead the industry trend storm,

promote the entire stone processing lean production,

Weihong work with you